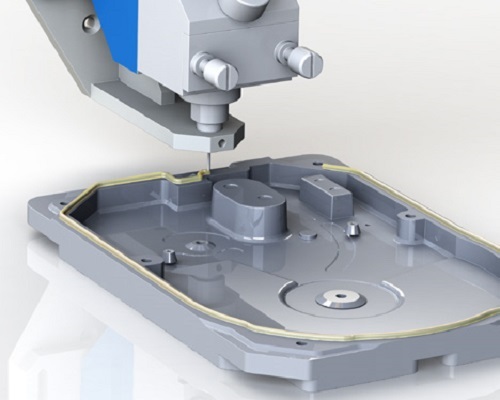

The material is drawn from the feeder into the internal metering chamber. The piston in the metering chamber is then moved via a spindle with servo drive and the material is metered. the material is dispensed. If the quantity present in the dispensing chamber is less than the next quantity to be dispensed, the internal dispensing chamber is filled again. The internal dispensing chamber of the MPP1 has a volume of 0.17 ml, so that dispensing quantities between 0.001 ml and 0.170 ml can be realised. The dosing chamber of the MPP3 can hold either 5 mm or 7 ml. The digital control unit controls dispensing and refilling of the internal cartridge. Disping quantity and dispensing speed can be be programmed as parameter sets. Up to 400 parameter sets can be predefined. The integration into control systems of automated plants is carried out via digital IOs.

Materials with a viscosity of 1-100,000 Pa-s can be processed. Typical quantities are 0.005ml to 0.1ml. Typical applications are potting of LEDs, optical and electronic components, web dispensing of sealants, and dispensing of silicone-based adhesives.

The unit is suitable for applications such as underfilling and potting, precise and constant filling with oil, injecting electrolyte solution into batteries of different types, dispensing ink, etc.

| Measuring Master MPP-1 | Measuring Master MPP-3 | Measuring Master MPP-3 DUO | |

|---|---|---|---|

| Dispensing method | Piston dispensing valve | Piston dispensing valve | Piston dispensing valve |

| Viscosity material | 1-50.000 mPa*s | 1-100.000 mPa*s | 1-100.000 mPa*s |

| Smallest point sizes | 0,2-0,3 mm | 0,2-0,3 mm | 0,2-0,3 mm |

| Feed | Cartridge 5-70 ml | Cartridge 170-330 ml / Tank | Cartridge 330-600 ml / Tank |

| Weight dispensing head | 0,8-0,9 kg | 4,0-5,0 kg | 10,0-12,0 kg |

| Controller dimensions | 300x250x111 mm | 300x250x111 mm | 2x 300x250x111 mm |

| Max. distance controller -dosing head | 10 m | 10 m | 10 m |

| Parameter | Quantity, Speed | Quantity, Speed | Quantity, Speed |

| Number parameter sets | 400 | 400 | 400 |

| Functios | Retreat, Refill | Retreat Refill | Retreat, Refill |

Do you have any questions? We will be happy to advise you. Please send us your inquiry to info@atn-berlin.de.

|

Cookie Settings ATN |

|

|

Technical cookies for advanced functions of the ATN website. Please note our Privacy policy. |

|

|

Other supplier |

|

| Cookies from Google, Youtube and Google Maps* *Google, YouTube und Google Maps are offers of Google Ireland Limited |

|

| The privacy policies and terms of use of the respective third-party providers can be found on their websites. | |